===

As we delve into 2024 trends in automotive 3D printing, the industry stands on the precipice of transformative change. Traditional manufacturing methods are often riddled with inefficiencies, high costs, and lengthy production times that frustrate automotive innovators and manufacturers alike. The urgency for a solution that not only enhances productivity but also enables customization has never been clearer. This exploration reveals the cutting-edge innovations in 3D printing, designed to meet the demands of modern vehicle manufacturing while addressing the pressing issues of sustainability and efficiency.

Revolutionizing Vehicle Manufacturing with 3D Printing in 2024

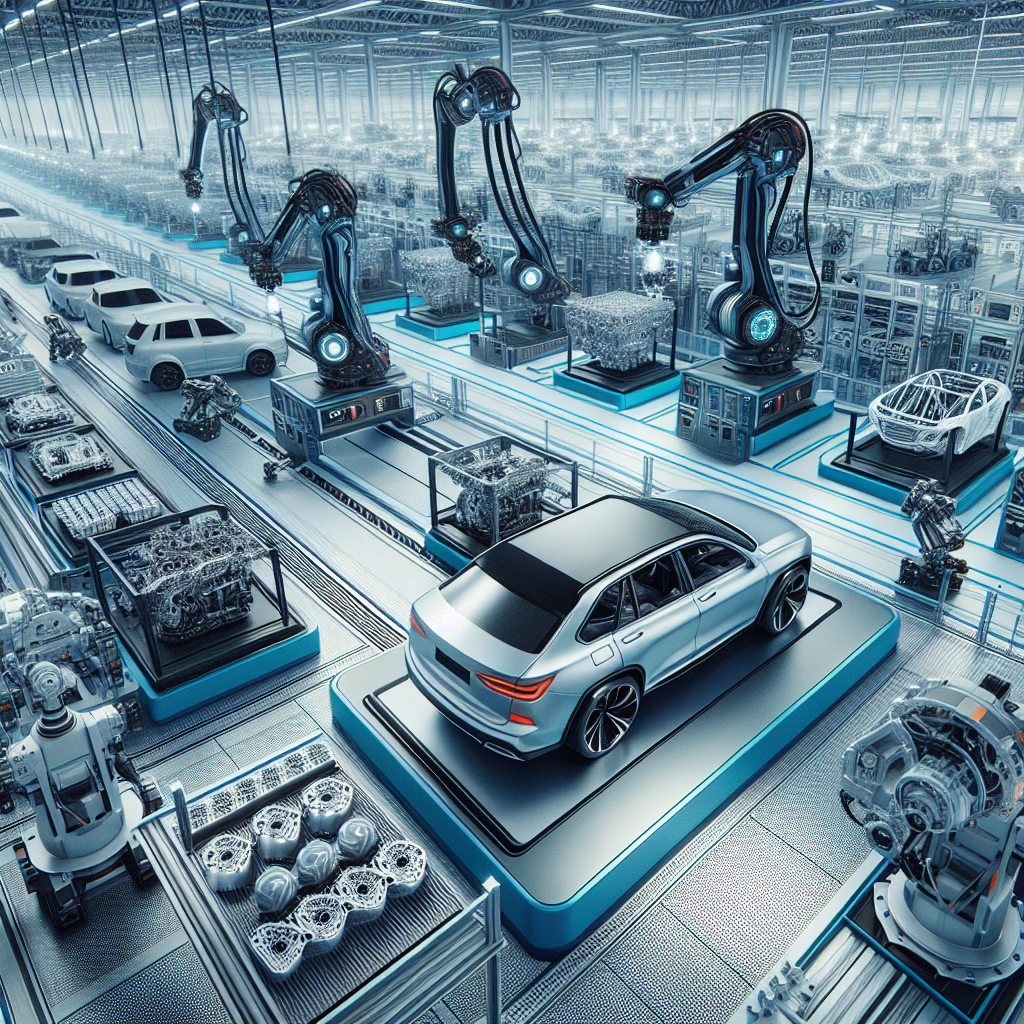

In 2024, automotive manufacturing is witnessing a paradigm shift thanks to advancements in 3D printing technologies. This innovative approach allows manufacturers to produce complex geometries and lightweight components that were previously impossible or cost-prohibitive. By leveraging additive manufacturing, companies can significantly reduce the time required for prototyping and production, allowing for rapid iterations that keep pace with evolving consumer demands. This agility not only enhances productivity but also positions manufacturers to respond quickly to market changes.

Moreover, the integration of 3D printing into the supply chain is revolutionizing inventory management. With on-demand production capabilities, manufacturers can minimize the need for extensive warehousing. Parts can be printed as needed, reducing storage costs and waste associated with excess inventory. This just-in-time manufacturing model allows automotive companies to optimize their resources while simultaneously addressing the pressing issue of supply chain vulnerabilities, a concern that has been magnified in recent years.

As we move through 2024, the adoption of 3D printing is not limited to the production of components but is also playing a crucial role in vehicle assembly processes. With the advent of large-scale 3D printers capable of fabricating entire vehicle sections, the automotive industry is poised to embrace a future where assembly lines are more flexible and less dependent on traditional tooling. This shift not only enhances manufacturing efficiency but also opens the door for increasingly personalized vehicle designs, meeting the growing consumer demand for unique automotive experiences.

Key Trends Shaping Automotive 3D Printing Technologies

Several key trends are emerging as the automotive industry embraces 3D printing technologies. One significant trend is the rise of advanced materials that enhance durability and performance. Innovations in polymers and metal alloys specifically engineered for 3D printing are enabling manufacturers to create components that can withstand the rigors of automotive applications. These materials allow for the production of parts that are both lightweight and robust, ensuring vehicles are not only fuel-efficient but also high-performing.

Another noteworthy trend is the increasing use of artificial intelligence (AI) and machine learning in the 3D printing process. These technologies provide manufacturers with the capabilities to optimize print settings, predict failures, and analyze data for continuous improvement. By marrying AI with 3D printing, the automotive industry can achieve unprecedented efficiencies, reducing waste and enhancing the overall quality of printed components. This integration is paving the way for a smarter manufacturing landscape where decisions are data-driven, leading to superior outcomes.

Additionally, the exploration of hybrid manufacturing, which combines traditional manufacturing methods with 3D printing, is gaining traction. This approach allows manufacturers to utilize the strengths of both techniques, resulting in cost-effective solutions that maintain high standards of quality. Hybrid manufacturing not only accelerates production times but also facilitates the integration of custom and complex components into existing manufacturing processes, providing a seamless transition into the realm of advanced manufacturing.

Sustainable Practices: Eco-Friendly Materials in Focus

Sustainability is becoming a cornerstone of automotive 3D printing in 2024. As environmental concerns grow, manufacturers are increasingly seeking eco-friendly materials that can replace traditional, less sustainable options. Innovations in bioplastics and recycled materials are leading the charge, offering a greener alternative for vehicle components while maintaining performance and durability. These materials not only reduce the carbon footprint associated with automotive manufacturing but also appeal to a consumer base that is increasingly environmentally conscious.

The adoption of sustainable practices extends beyond materials to encompass the entire manufacturing lifecycle. Techniques such as energy-efficient printing processes and waste reduction strategies are becoming standard practices. For instance, manufacturers are implementing closed-loop systems that recycle waste material generated during printing, further minimizing environmental impact. In 2024, the ability to produce parts on-demand means less waste associated with overproduction, making 3D printing an inherently more sustainable option in the automotive sector.

Moreover, sustainability in automotive 3D printing is gaining support from regulatory bodies and consumer organizations alike. As governments worldwide push for greener practices within manufacturing sectors, automotive companies are responding by embracing 3D printing as a vehicle for achieving their sustainability goals. This alignment not only enhances brand reputation but also positions companies as leaders in an industry that is rapidly evolving towards eco-friendly solutions.

Case Studies: Successful Implementations in the Industry

Several automotive manufacturers have already begun to showcase the benefits of 3D printing, serving as beacons of innovation in the industry. For example, a leading automotive company recently designed and produced a complex cooling duct using 3D printing technology, achieving a weight reduction of nearly 40% compared to traditional manufacturing methods. This project not only improved vehicle performance but also highlighted the potential for significant cost savings in material usage and production timelines.

Another compelling example involves an electric vehicle manufacturer that utilized 3D printing to create customized interior components. By leveraging this technology, the company was able to offer a level of personalization that set it apart from competitors. Customers could select from various designs and materials, resulting in a unique automotive experience tailored to individual preferences. This successful implementation demonstrates how 3D printing can enhance consumer engagement and satisfaction while driving sales.

Lastly, a well-known automotive parts supplier has integrated 3D printing into its production line to create tools and fixtures. By adopting this approach, the supplier significantly reduced lead times for tool creation, enabling faster turnaround for component production. This case illustrates the potential for 3D printing to enhance not just product offerings but also internal processes, leading to greater efficiency and competitiveness in the automotive market.

===

The advancements observed in 2024 trends in automotive 3D printing are indicative of a broader shift towards more innovative, efficient, and sustainable manufacturing practices. As automotive manufacturers increasingly harness the power of 3D printing, the implications for efficiency, customization, and environmental responsibility cannot be overstated. Those who embrace these innovations will not only enhance their operational capabilities but also secure a competitive edge in a rapidly evolving market. Exploring these trends further can yield insights that drive your organization toward a more sustainable and innovative future. Engage with these advancements now and position your enterprise at the forefront of automotive manufacturing excellence.

Understanding 2024 Electric Vehicle Tax Incentives in CanadaExploring Augmented Reality Dashboards in Cars: 2024 InsightsKey Advancements in Automotive Lidar Technology for 2024Relevant LinkRelevant LinkRelevant Link2024 Automotive Cybersecurity Standards: Ensuring Vehicle SafetyCurrent Availability of Hydrogen Fuel Cell Cars in CanadaOverview of Recent Autonomous Vehicle Regulations in OntarioRelevant LinkRelevant LinkRelevant Link